如何选择一家专业的可靠性强的激光焊接加工厂呢?

一、行业大客户背书案例

瑞士布勒Buhler (不锈钢食品级机械行业)

日本久保田Kubota (不锈钢化工、医药机械行业)

美国惠普Hp (不锈钢3D金属打印机行业)

丹麦迈克罗迈帝克Micro Matic (不锈钢啤酒设备行业)

西班牙西科特Cecotec (不锈钢消费者产品破壁料理机行业)

美国格林奈尔Grinnell (不锈钢管道行业)

台湾台达Delta (AI算力不锈钢水冷管行业)

讯强Cooler Master (AI算力不锈钢水冷管行业)

大陆的宏工、尚水、浩能、华为等(不锈钢设备及零件行业)

二、介绍自己

金珠2007-2025,持续18年不锈钢加工经验,为食品机械、化工机械、医疗医药器械、新能源设备(含设备零部件、功能组件)、光伏设备行业、半导体设备行业、厨卫行业、精密仪器仪表行业、3C消费类电子行业、建材装饰行业、户外装备设备行业、奢侈品标志展架及金属包装行业、航空航天部件、实验室设备部件、CNC机械加工模具拉伸冲压焊接件行业,共15个行业提供机械加工、钣金成型、及专业焊接加工服务。并获得欧洲、美国及日本等国家和地区的客户的信任和认可。

三、我们有什么产品

激光切割加工、数控折弯加工、数控冲压加工、数控卷圆加工、TIG/MIG焊接加工、激光焊接加工、打磨抛光、喷涂或电解抛光、组装、检测、包装出货。

四、核心产品重点介绍原理

焊接(尤其是TIG/MIG焊接加工、和激光焊接加工)

可以把焊接做到极致效果并达到客户的要求,因为有长达20年的焊接解决方案(有效解决因为材料学、结构、外观、功能、应用、及成本等方面的诸多痛点问题)

五、为什么选择我们

1、有长达20年的海外产品应用及要求的丰富综合解决问题的经验,有众多实际 量产案例背书;

2、有我们自己的核心竞争力的同时,有超强的上下游资源来协助解决问题;

3、有工艺迭代能力及新产品高确定性开发能力;

六、我们有哪些优势

1、行业应用经验非常丰富,当客户告知我们他的行业,我们就能从过往的客户数据库应用经验迅速调用工艺解决方案,并沟通图纸要求及产品要求,能有效减少开发时间及准确达到客户的设计要求。

2、当自身条件和能力不足时(主要是硬件加工设备及特殊工艺瓶颈),有足够上下游资源来共同解决,并能专业且有效地甄选和管控这些T2供应商;

3、能够指出客户设计不合理的、或者是后制程工序难以做到(或者能做到但成本太高而造成浪费),并就这些能提出ID改进、改善、甚至设计变更的有效建议,提交客户审核确认。实事有N多客户因为我们的此项能力而受益并使项目顺利如期落地实施。

七、疑难解答

1、问:材质问题,是否符合要求?

答:材质方面,我们一直以图纸要求,提供国际标准成分的材料,并提供材质报告证明。

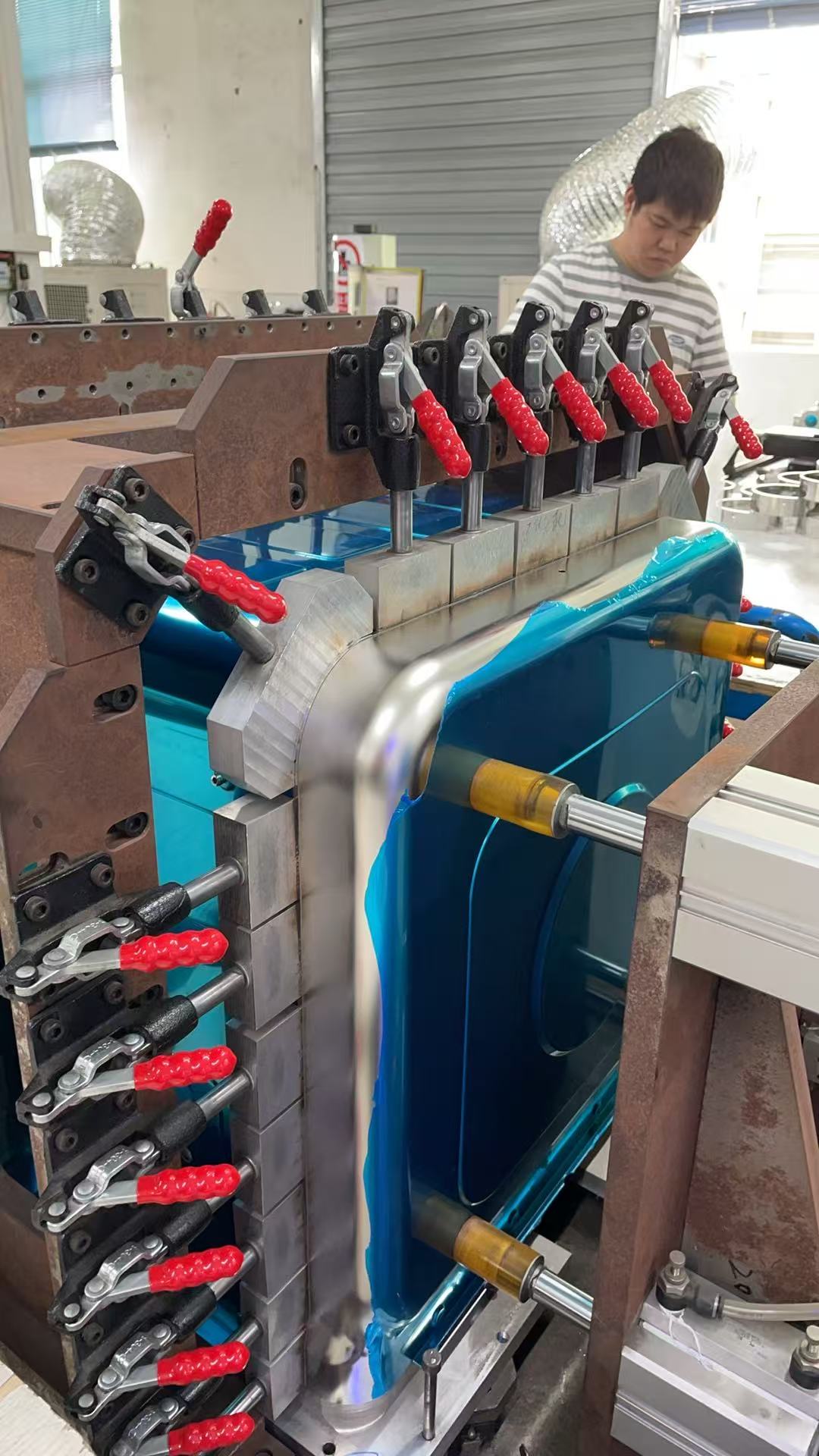

2、问:如何保证产品在加工过程中的一致性?

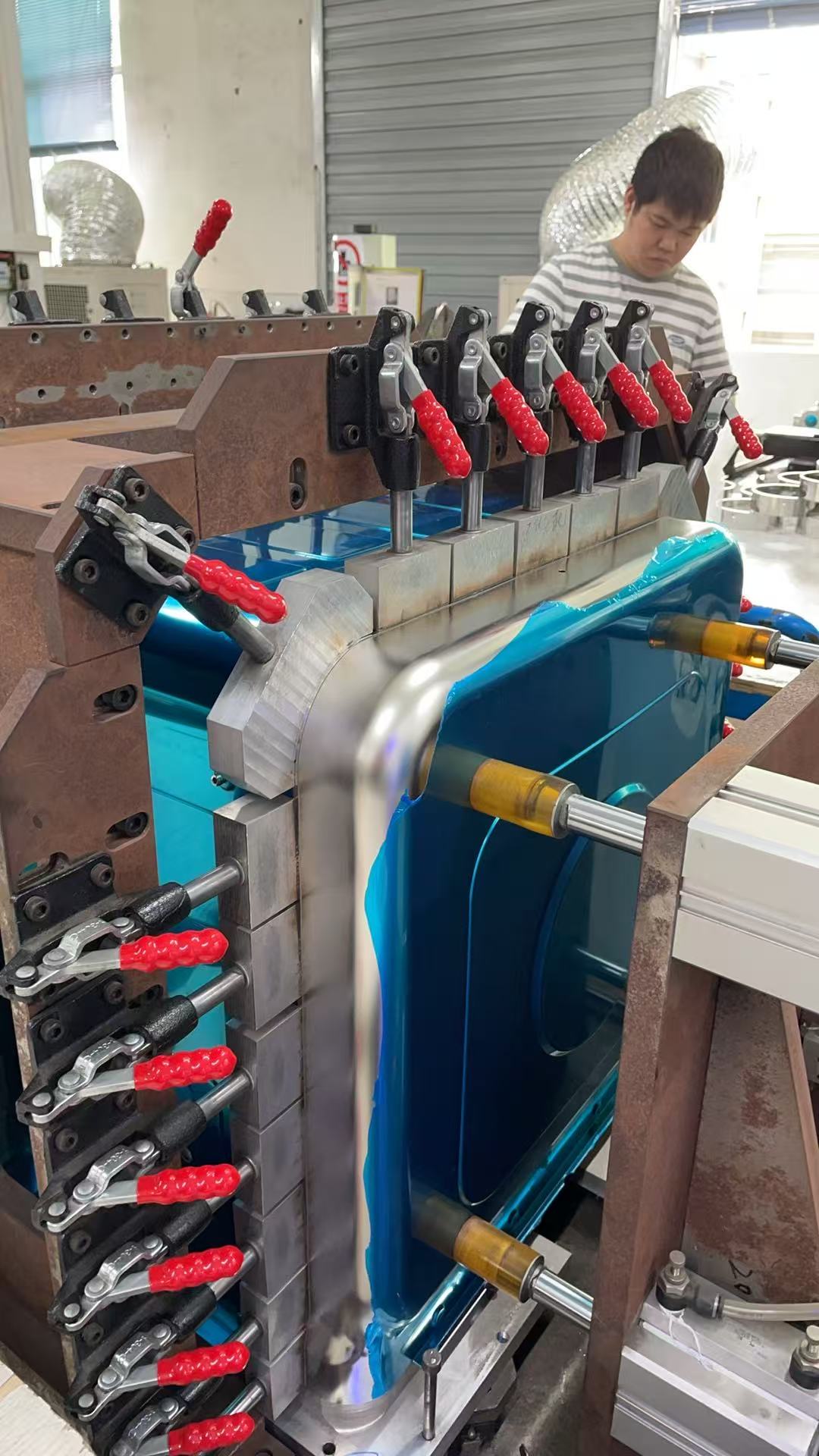

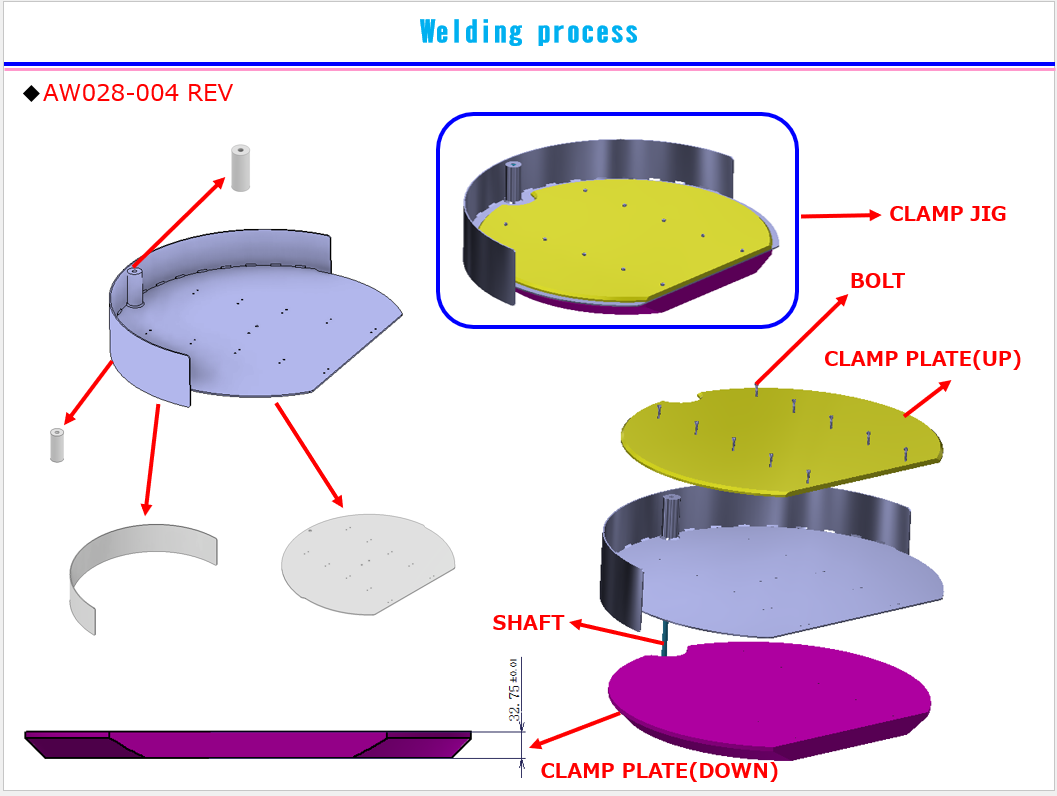

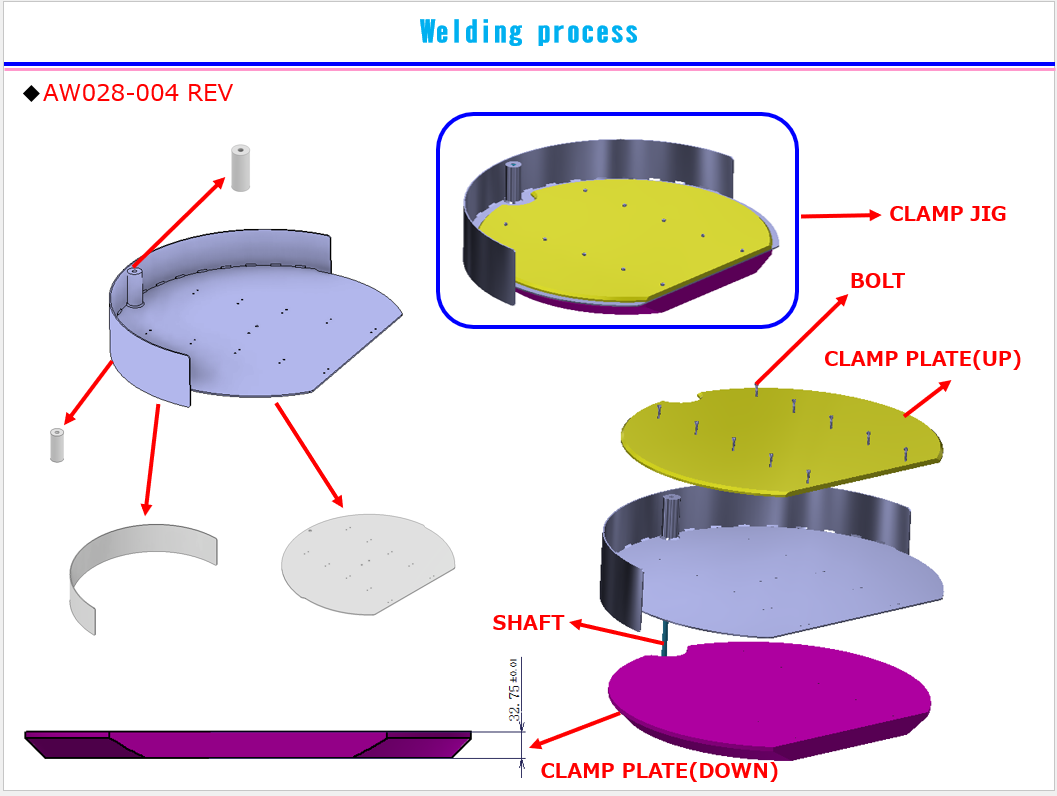

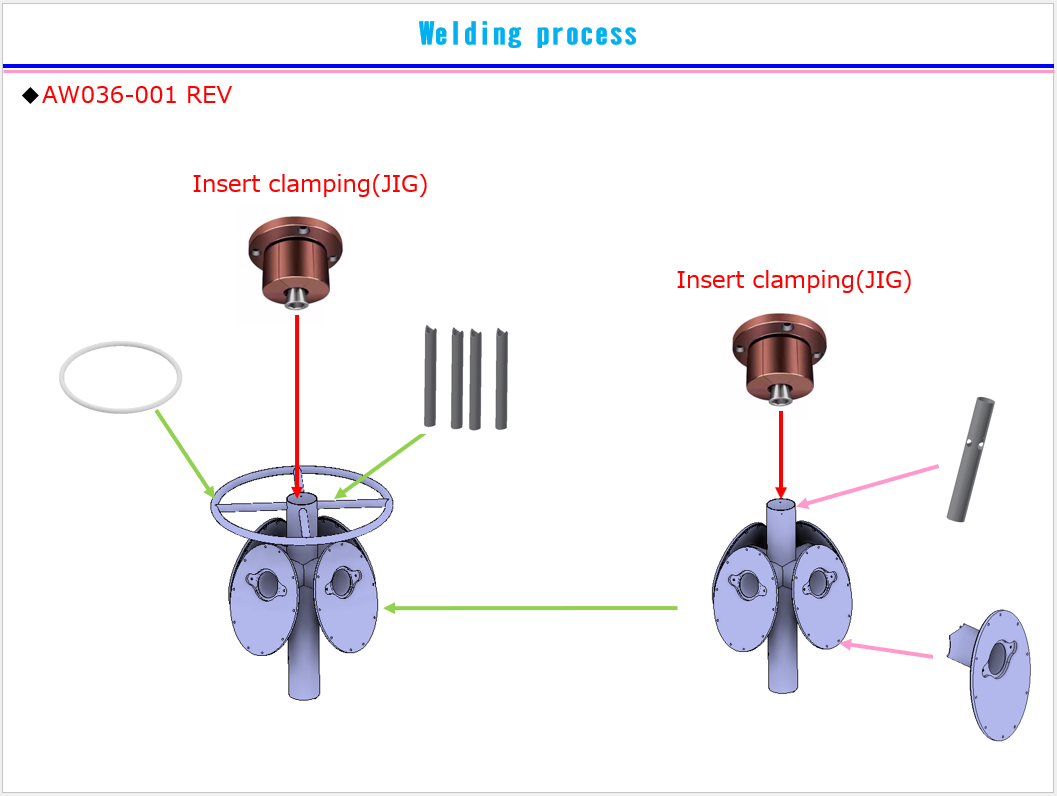

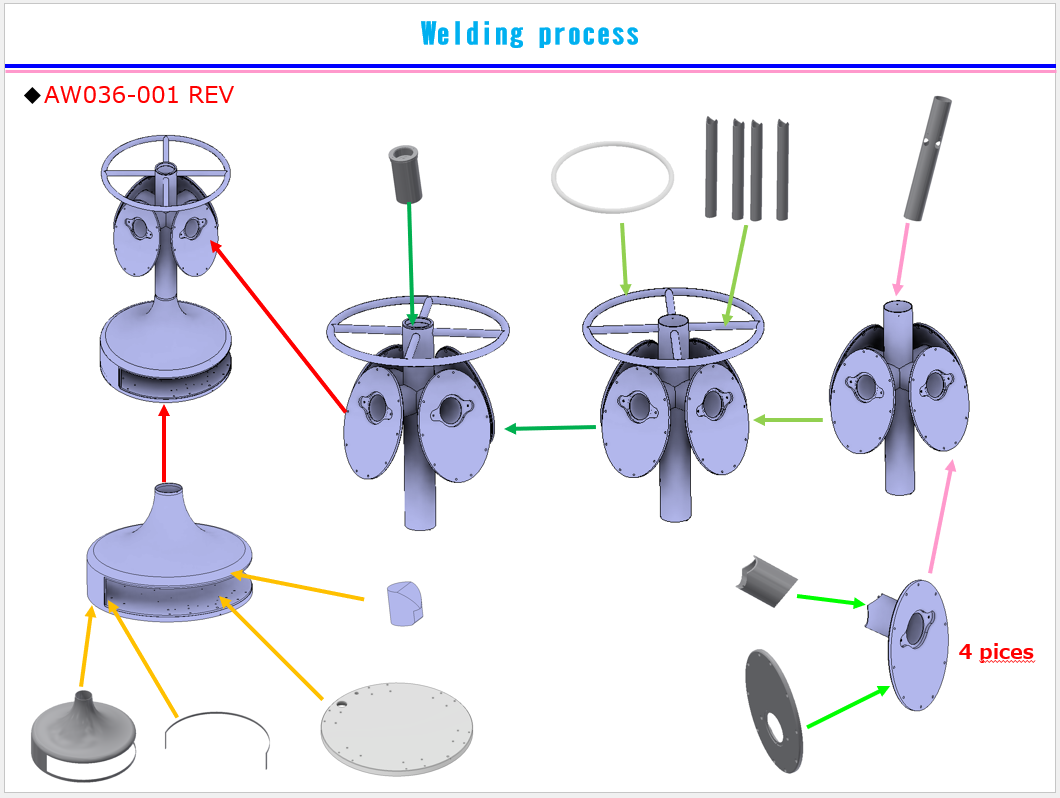

答:我们能设计与制作专业的产品加工工装,并提交客户讨论确认,并按确认后的工装形成加工SOP作业指导书来进行生产。

3、问:如何确保产品在生产过程中的良品率?

答:我们有ISO9001质量体系认证,并严格按质量体系的要求把产品加工过程中,从操作人员、机器设备、物料、工艺方法、加工环境(含周转、摆放、安全)、检测等环节全部形成闭环管控到位,并按照来料检验、过程检验、及出货检验的流程来操作,以确保100%的良品率。

4、问:如何确保保质、保量、按时交付?

答:我们会通过生产交付管理软件,动态地显示订单要求的交付日期、材料在途和到料的时间和状态、生产每一个环节工序的完成时间和状态(如遇异常,会显示对应的颜色提醒,并有上传异常的产品照片及图纸指示位置圈记,同时马上安排核查原因,是客户的问题会马上跟客户沟通、是自己的问题会马上想办法并解决这个问题至正常状态变成绿色,使生产工序向下一步骤继续流转,所以工序都可追溯并查清到哪个时间节点、哪个班组到具体操作人员,所有的时间设定都是与跟客户沟通承诺的时间来设定,只许提前,不许推后。这样,就能做到按时交付。

八、订购流程

与客户接洽沟通时,会请客户填写客户需求信息表→由总工程师召集业务、技术、工程、生产、品质、采购、PMC部门及人员一起评估客户的产品及要求→把评估会议内容整理成沟通语言后由业务跟单与客户联系并沟通确认→当我们已完全清楚并了解客户要求后、客户也完全了解和清楚我们的方案后,达成共同技术、图纸、数量、品质要求、交付要求后→出具报价单→客户确认报价单→客户或者我们出具商务合同并相互确认条款→客户出具正式的PO订单→我们按前面的技术确认书及PO订单启动生产交付程序→生产过程及完工后动态确认文件生成→客户出具验收确认单→按商务合同支付货款→出货物流

九、客户合作反馈

所有客户都有收货后的反馈意见书,并保存在项目信息反馈栏里,如有投诉,我们会出具8D品质改善报告,客户确认后的改善方案一并记录在项目信息里,以便翻单时按改善后的正确方式执行下一个订单。

十、提交需求表单

客户通过跟我们的业务人员沟通后,觉得能选择我们,并有合作意向,请提交基本的需求表单信息,我们会在工作日24小时内响应并反馈信息。

不锈钢加工案例:

一、食品级不锈钢产品

项目概况

国别:瑞士

行业:食品机械

材质:304不锈钢

数量:200个/年

痛点:客户要求用一种焊接方式替代原来的不环保的钎焊工艺,并且成形成单件流的精益生产供应方式。

项目挑战

1、虽然价值高,但数量少;

2、传统TIG焊接(中国叫氩弧焊),变形量大,会导致尺寸不精准,且表面抛光是瓶颈。

解决方案

1、采用激光焊接(无介质),微变形,并解决原钎焊里的铅带来的环保问题。

2、采用钣金折弯和组焊,解决单件流难题。

3、采用焊前将零件预抛光后再焊接,解决结构遮挡,难以抛光的瓶颈。

项目成功

1、客户惊奇找到了合适的、几乎达所有解决痛点要素的工艺方案。

2、模具拉伸、钣金折弯、激光焊接,抛光成镜面,电解抛光成成品。

3、客户用金珠的方案由原来8款产品推广到全集团同类结构的80款产品。

产品生产履行过程

1、客户产品图纸要求的沟通

2、通过激光切割、模具拉伸、CNC加工、折弯、卷圆、TIG/MIG焊接、激光焊接laser welding、打磨抛光、电解、检测、包装、出货。

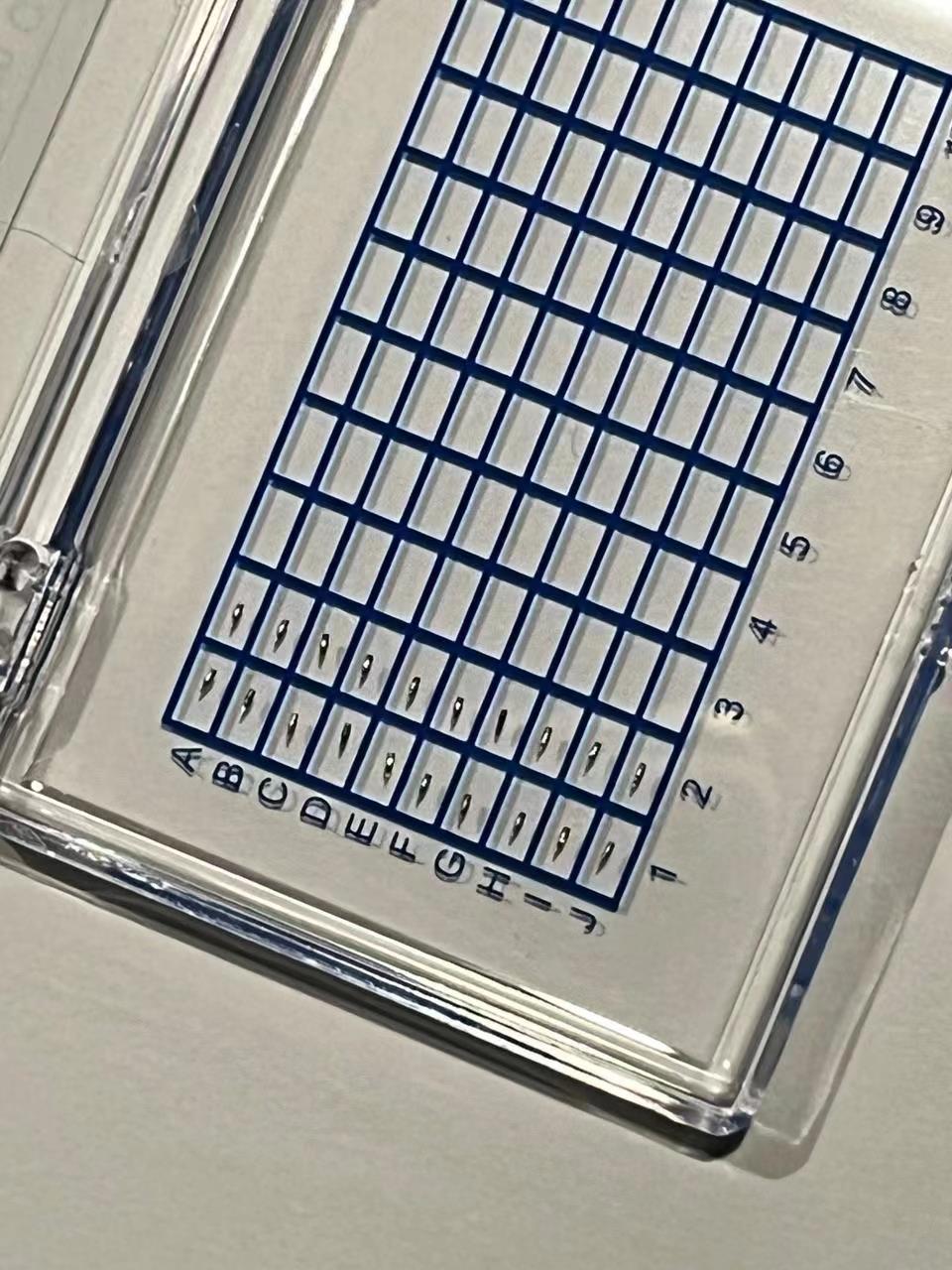

二、医疗级不锈钢产品

美国不锈钢医疗器械客户(行业前三名)

项目概况

国别:美国(医疗器械行业前三名公司)

行业:医疗机械(耗材,一次性的,用了就丢弃,再订购补充)

材质:316不锈钢

数量:四个产品,每个产品数量都过万个了。

价值:四款产品加起来,总订单额在2000W左右。

工艺要求:模具成型+精密机械加工+精密激光焊接(微变形)+抛光+清洗+检测

痛点:医疗器械要求极高,找中国生产,认证由客户在美国完成(早已认证过了的);

很难找到精密激光焊接的厂商

要求有专业的清洗条件,并无菌包装;

要有专业的光学检测仪器

项目挑战

1、加工没有问题、焊接没有问题(激光焊接);

2、清洗和检测可以。

解决方案

3、采用激光焊接(无介质),微变形,医疗器械基本上全采用的激光焊接。

总结:

一、我们为客户提供以下产品及服务,包括产品的整体解决方案

1、生产工序:

A:激光切割加工、

B:数控折弯加工、

C:数控冲压加工、

D:数控卷圆加工、

E:TIG/MIG焊接加工、

F:激光焊接加工、

J:打磨抛光、喷涂或电解抛光、组装

ABCDEFJ共七道工序,这七道工序,

1、既能独立每一道工序就能形成一笔订单;

2、也可以其中任两三道工序组合形成订单;

3、也有客户有时候需要全部七个服务,形成订单;

4、还有一种情况就是他找齐了其中六道工序,唯独找不到激光焊接, 也会找到我们,要求他先前的供应商指定我们做激光焊接的服务,因为他在市场上 和他的供应商一起都没有找到比我们做得更好的激光焊接的配套商。

5、交谈中、合作中,因为激光焊接技术很关键,又比较偏门时,这时候有可能客户要求我们金珠为主供应商承接订单,来推动次要、泛市场随处可找的其它供应商来配套我们。

二、我们为客户提供的具体产品及服务,涵盖以下关键词

2、 产品及服务:

A:基础金属材料类

1、 Metal Sheet / 金属板材

2、 Stainless Steel / 不锈钢

3、 Aluminum Alloy / 铝合金

4、 Brass Plate / 黄铜板

B:金属加工形态类

1、 Metal Fabrication / 金属制造加工 - 核心服务词

2、 Sheet Metal Fabrication / 钣金加工 - 精准客户群

3、 Laser Cutting Service / 激光切割服务 - 技术型买家

4、 Metal Bending Service / 金属折弯服务 - 配套加工

5、 CNC Machining Parts / CNC机加工件 - 精密零件需求

6、 Metal Stamping Parts / 金属冲压件 - 汽车/电子供应链

7、 Welding Service / 焊接服务 - 加工能力关键词

8、 TIG/MIG焊接服务、laser welding激光焊接服务

9、 Stainless steel welding (TIG/MIG): 不锈钢焊接 (TIG/氩弧焊, MIG/熔化极气保焊)

C:成品与组件类

1、 Custom Metal Parts / 定制金属零件 - OEM买家

2、 Precision Metal Components / 精密金属部件 - 高端制造

3、 Metal Cabinet / 金属机柜 - 电气/控制设备

4、 Metal Bracket / 金属支架 - 泛工业应用

5、 Metal Enclosure / 金属外壳 - 电子设备防护

6、 Architectural Metalwork / 建筑金属构件 - 工程项目

D:行业应用场景

1、 Industrial Metal Fabricator / 工业金属制造商 - B2B客户

2、 Food Grade Stainless Steel / 食品级不锈钢 – 食品餐饮设备商

3、 Medical Device Metal Parts / 医疗器械金属件 - 高要求领域

4、 Stainless Steel Equipment and Components for the Semiconductor Industry/半导体行业不锈钢设备及零件

5、 Automotive Metal Parts / 汽车金属零件 - 汽配供应链

6、 Food processing equipment parts: 食品加工设备零件 (不锈钢核心应用)

7、 Medical device components: 医疗器械零部件 (高精度,不锈钢/钛合金)

8、 Pharmaceutical equipment parts: 制药设备零件 (卫生级不锈钢)

9、 Semiconductor equipment parts: 半导体设备零件 (高洁净度不锈钢/特殊合金)

10、 Marine components: 船用零部件 (耐盐雾不锈钢/铝合金)

11、 Automotive metal parts: 汽车金属零件 (各种钢材/铝合金)

12、 Architectural metalwork: 建筑金属构件 (不锈钢/铝合金装饰/结构)

13、 HVAC components: 暖通空调零部件 (不锈钢/铜管件)

14、 Machinery spare parts: 机械备件 (各类金属件)

15、 Electronics enclosure suppliers - 电子机箱供应商

16、 Telecommunication metal parts - 通信金属部件

17、 Medical equipment metal housing - 医疗设备金属外壳

18、 Automotive sheet metal components - 汽车钣金件

19、 Solar panel mounting brackets - 太阳能支架

E:核心产品与工艺关键词 (Core Product & Process Keywords)

1、 Stainless steel fabrication: 不锈钢加工/制造

2、 Stainless steel machining: 不锈钢机加工

3、 Stainless steel components: 不锈钢零部件

4、 Stainless steel parts: 不锈钢零件

5、 Stainless steel products: 不锈钢产品

6、 Stainless steel structures: 不锈钢结构件

7、 Stainless steel assemblies: 不锈钢组件

8、 Sheet metal fabrication - 钣金加工

9、 Metal stamping - 金属冲压

10、 Laser cutting services - 激光切割服务

11、 CNC bending - CNC折弯

12、 Metal enclosure fabrication - 金属机箱加工

13、 Precision sheet metal - 精密钣金

14、 Custom metal parts - 定制金属零件

15、 Chassis fabrication - 机架加工

16、 Metal brackets OEM - 金属支架代工

17、 Welding assembly - 焊接组装

18、 welding fabrication services 焊接加工服务

19、 welding outsourcing 焊接外包

20、 robotic welding services 机器人焊接服务

21、 stainless steel welding 不锈钢焊接

22、 aluminum welding 铝材焊接

23、 sheet metal welding 钣金焊接

24、 structural steel welding 结构钢焊接

F:采购意图关键词 (Buying Intention Keywords)

1、 Supplier of metal components: 金属零部件供应商

2、 Outsource metal fabrication: 外包金属加工

3、 Custom metal parts manufacturer: 定制金属零件制造商

4、 Metal parts vendor: 金属零件供应商

5、 High precision metal parts: 高精度金属零件

6、 welding supplier 焊接供应商

7、 welding vendor 焊接厂商

8、 welding sourcing 焊接采购

9、 welding company 焊接公司

10、 welding provider 焊接服务提供商

J:客户类型关键词

1、 OEM sheet metal supplier - OEM钣金供应商

2、 Metal fabrication sourcing - 钣金加工采购

3、 Contract manufacturing RFQ - 代工生产询价

4、 Industrial equipment manufacturers - 工业设备制造商

5、 Hardware importers - 五金进口商

6、 Machinery parts buyers - 机械零件买家

ABCDEFJ共七个大类,这七个类别的产品及服务,

1、既能独立每一类就能形成一种产品或者服务;

2、也可以其中任两三类组合形成产品或者服务订单;

3、也有客户有时候需要全部七大类的服务,形成订单;

4、还有一种情况就是他找齐了其中六类,唯独找不到激光焊接, 也会找到我们,要求他先前的供应商指定我们做激光焊接的服务,因为他在市场上 和他的供应商一起都没有找到比我们做得更好的激光焊接的配套服务商。

5、 有需要以上七类产品或者服务的客户,我们是首选供应商,请联系我们。

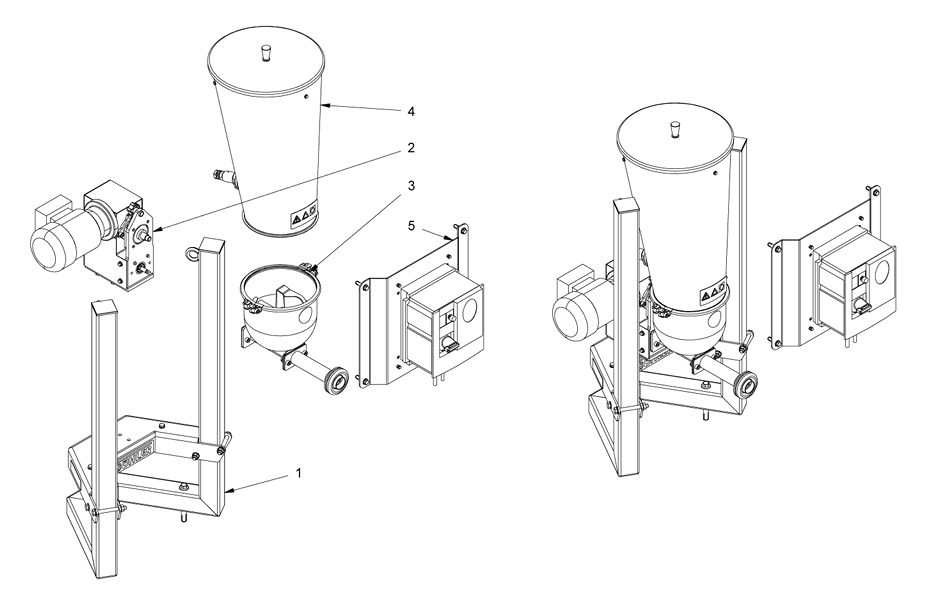

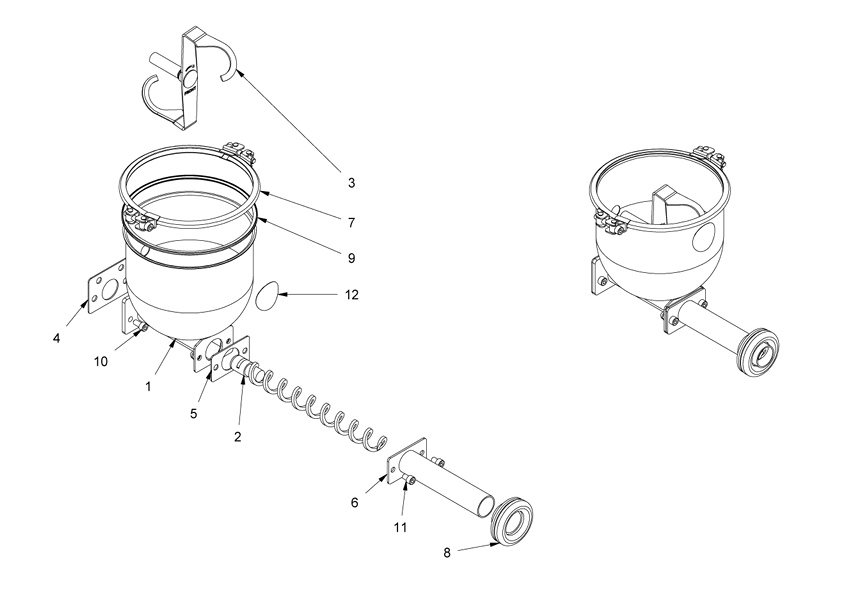

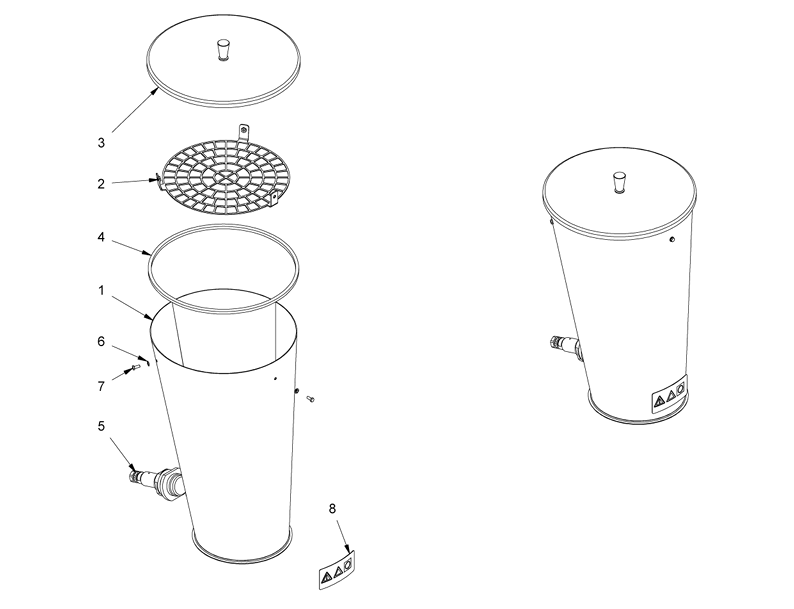

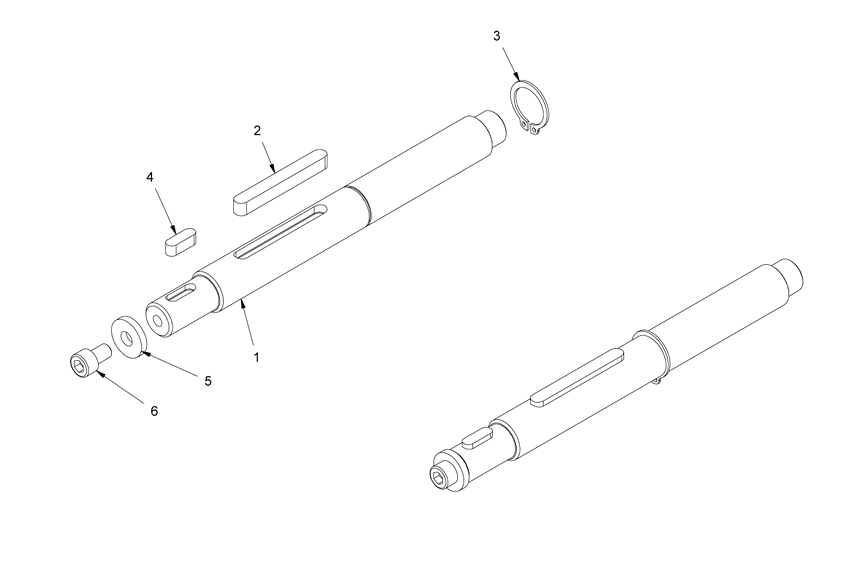

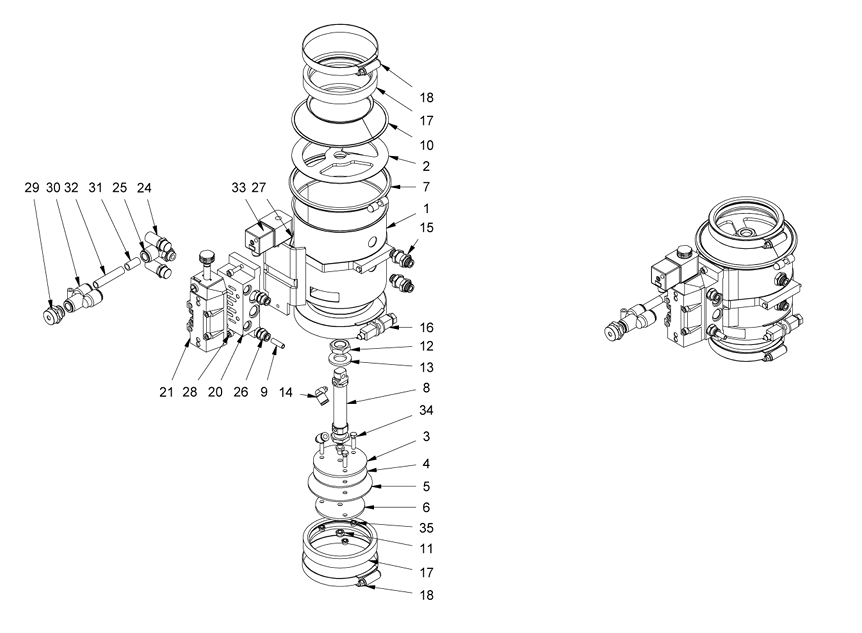

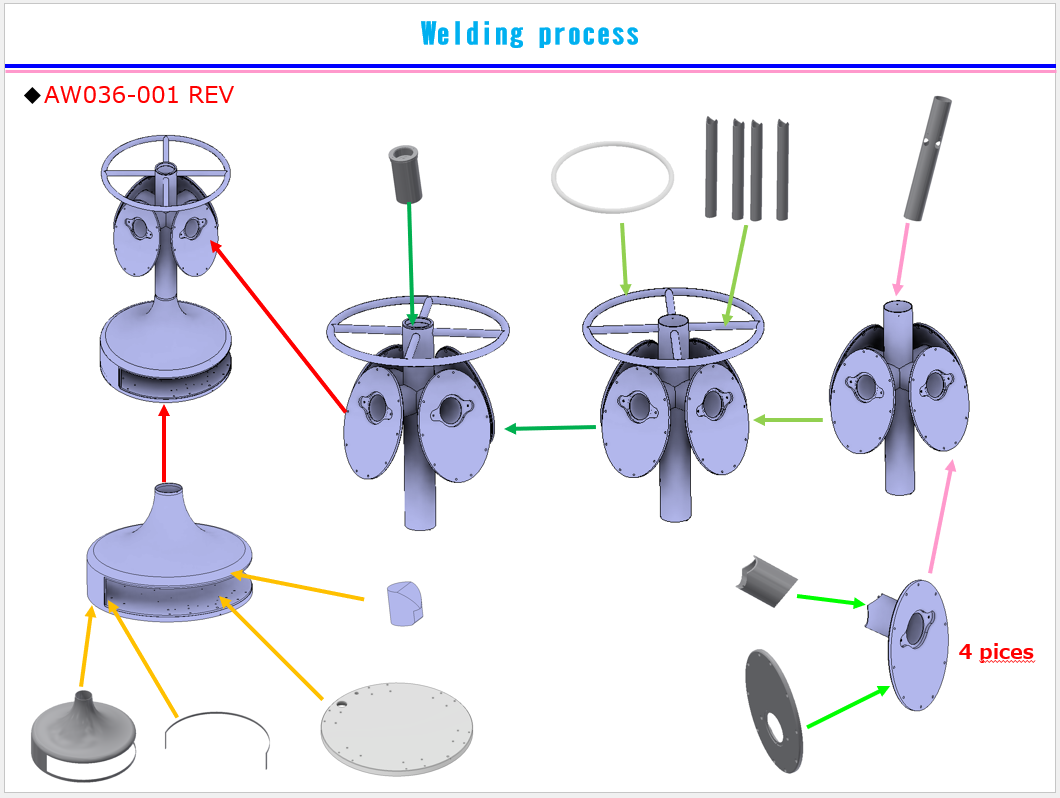

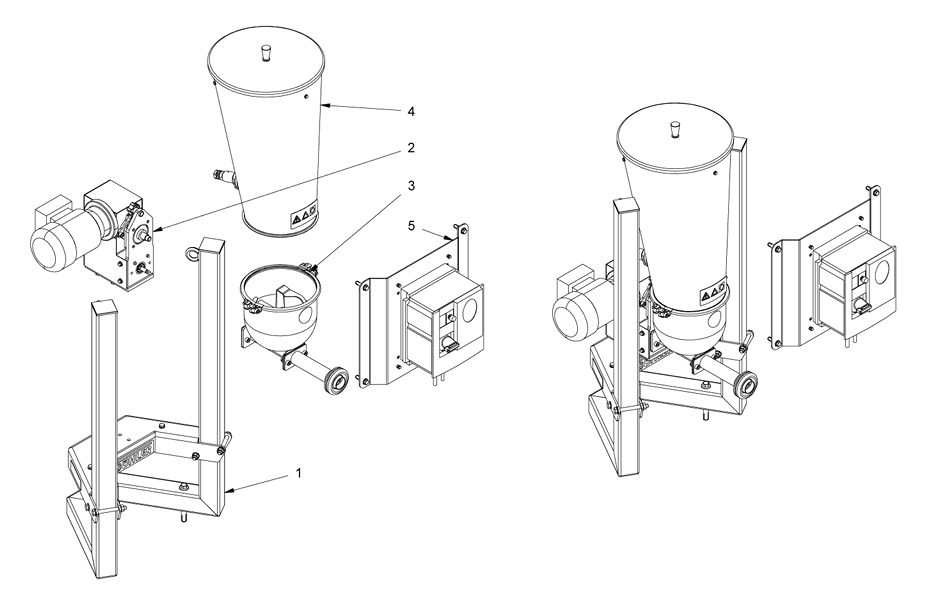

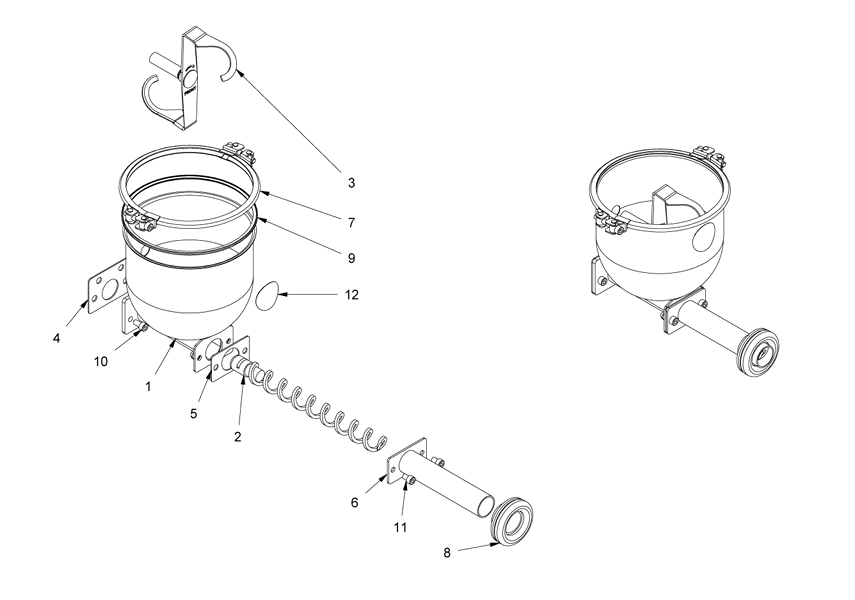

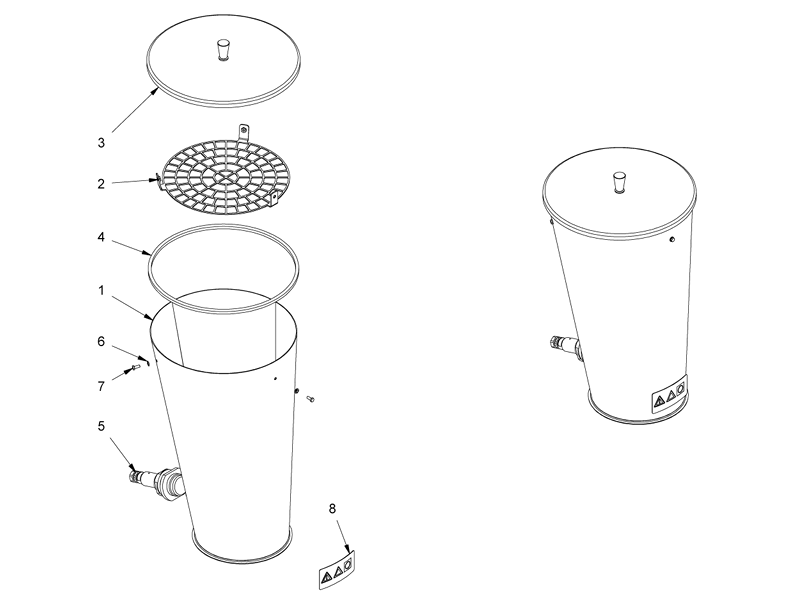

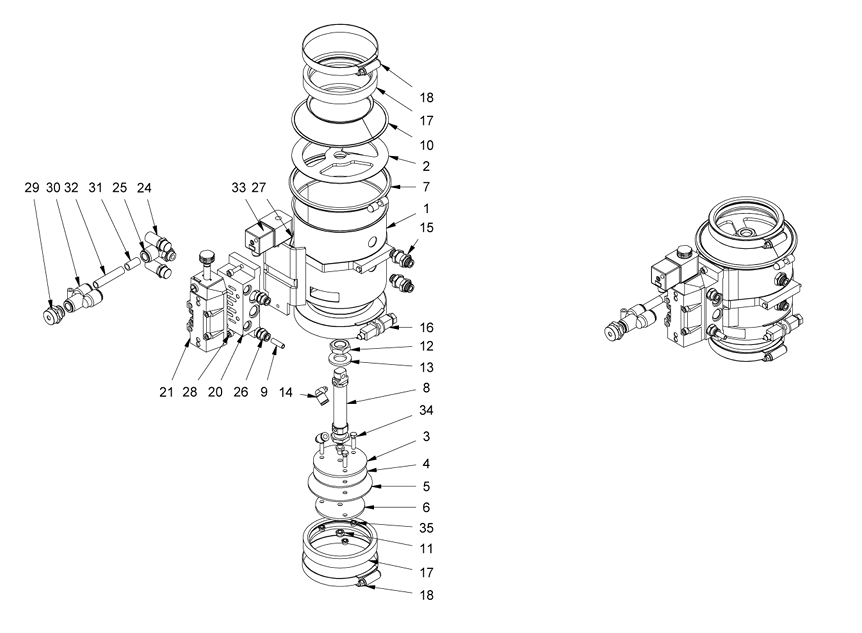

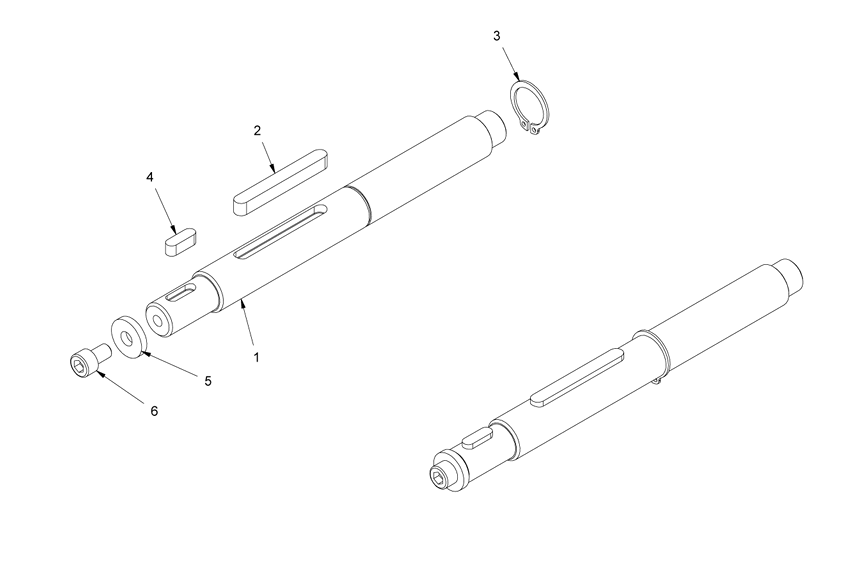

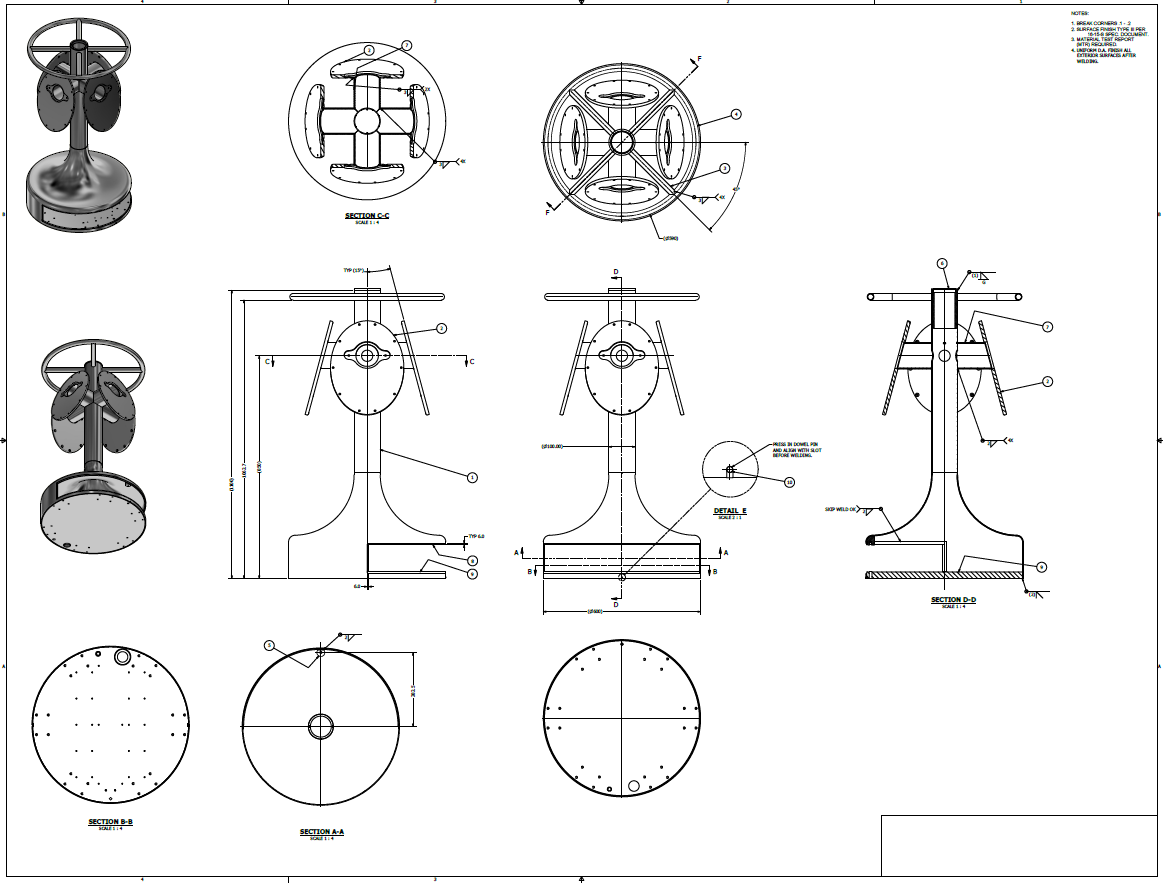

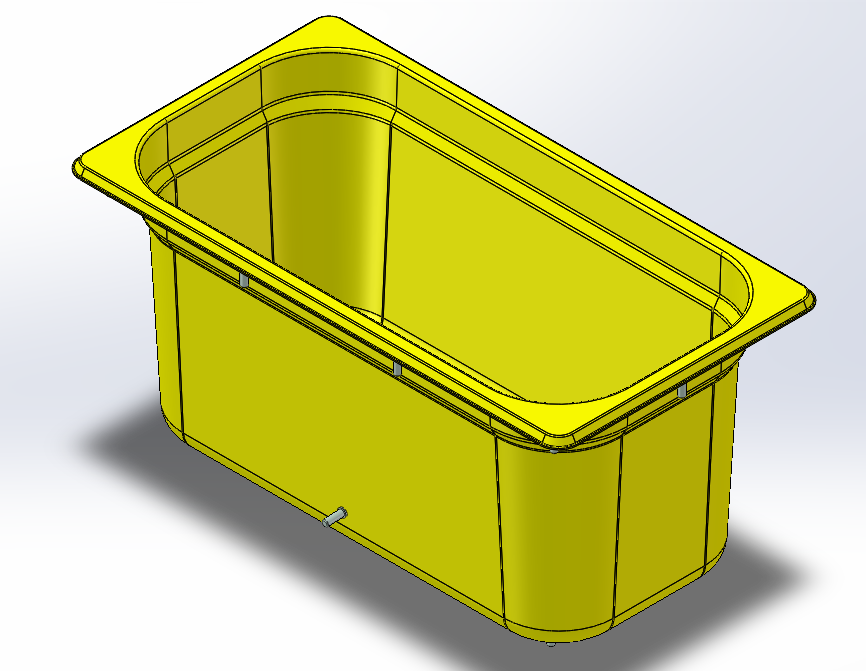

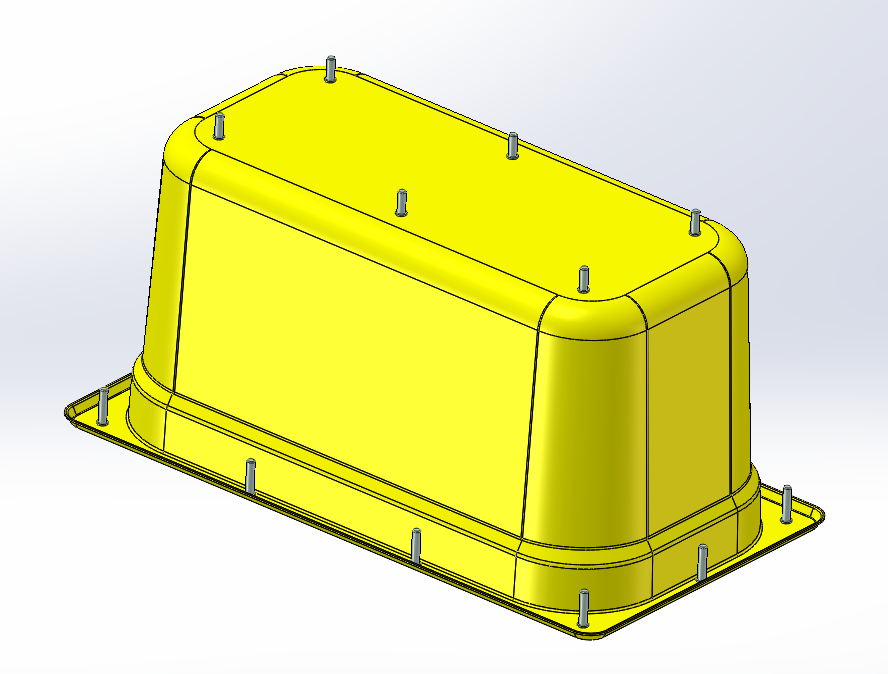

举例:2025年10月 美国某知名生物制药公司,要我们解决如下产品整体产品的生产与加工制造。

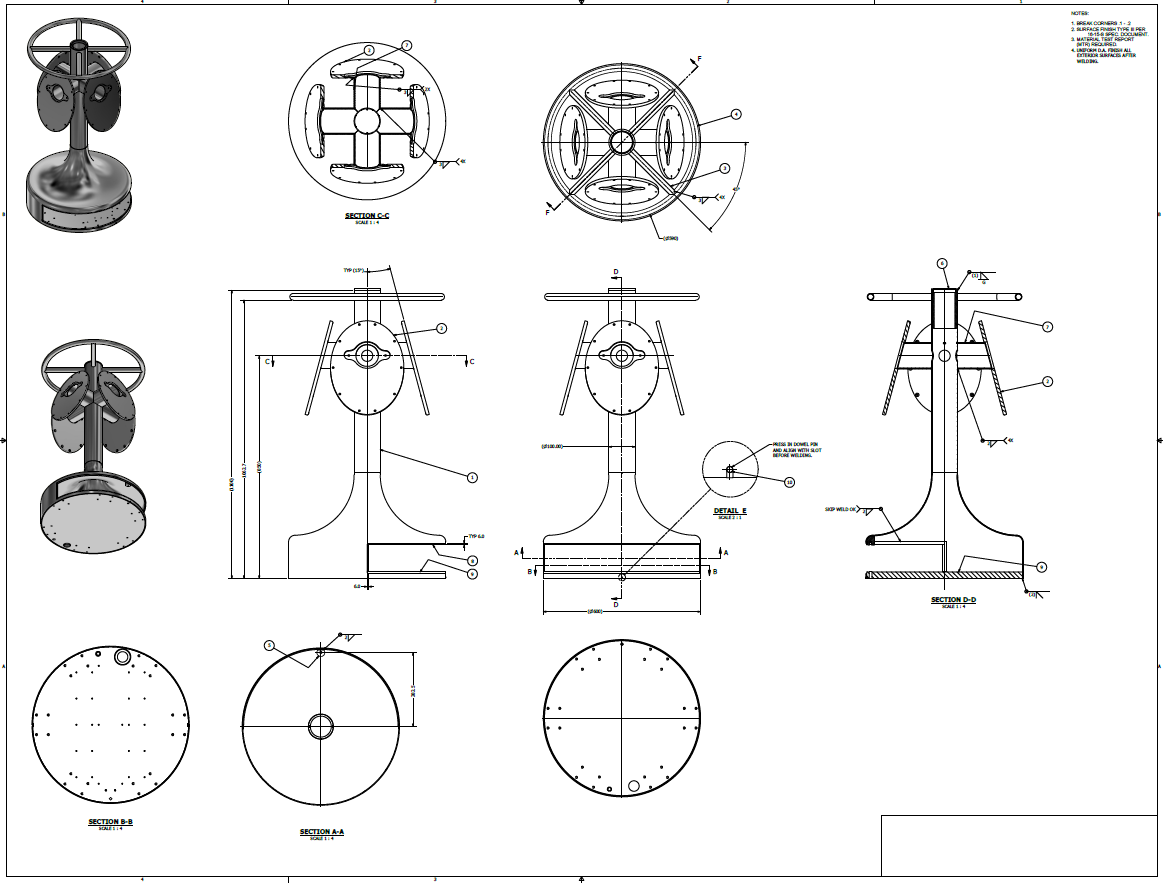

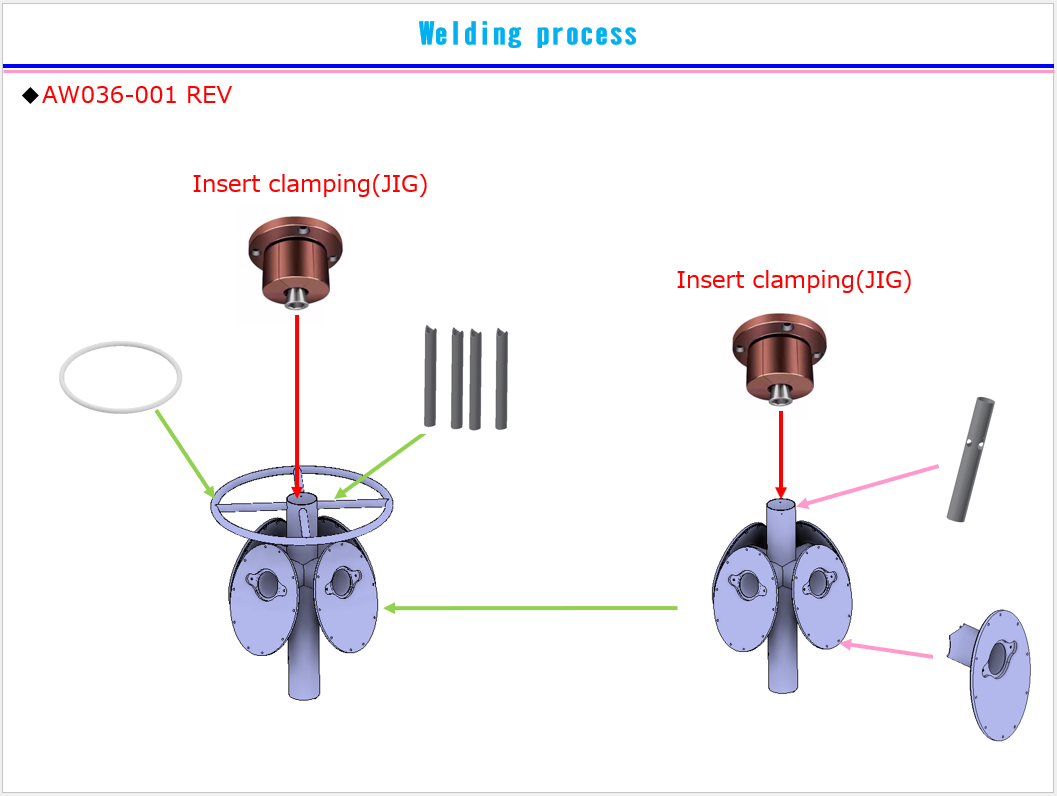

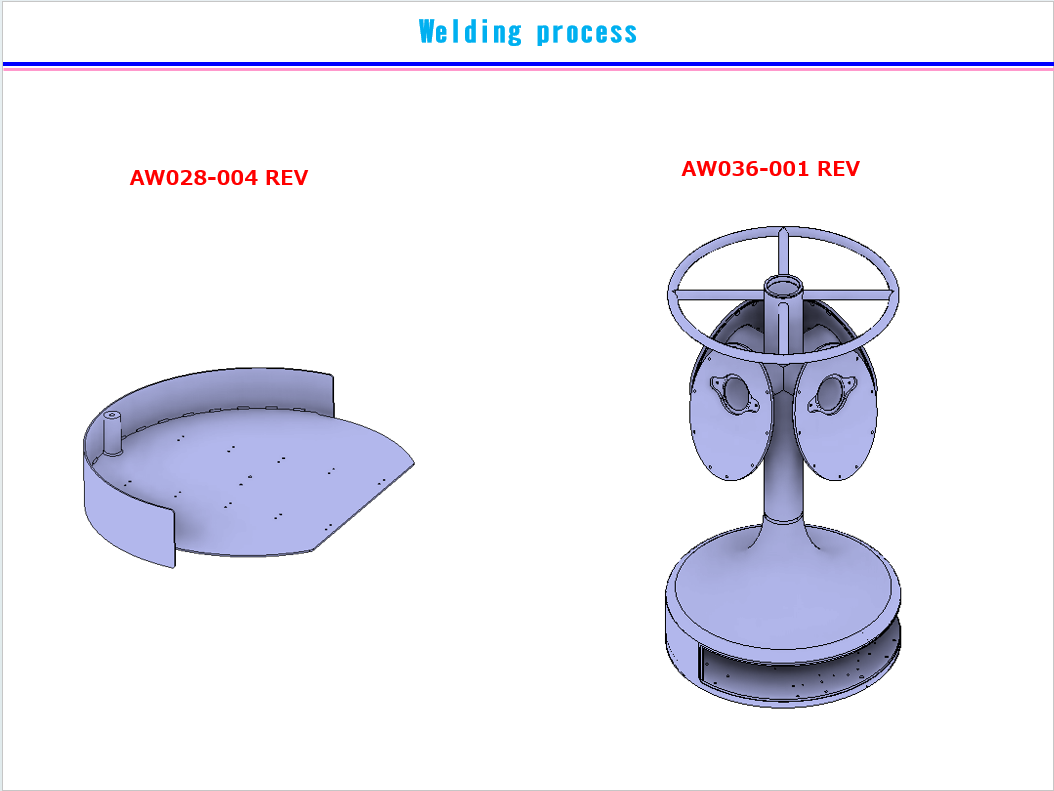

客户给图及交流要求

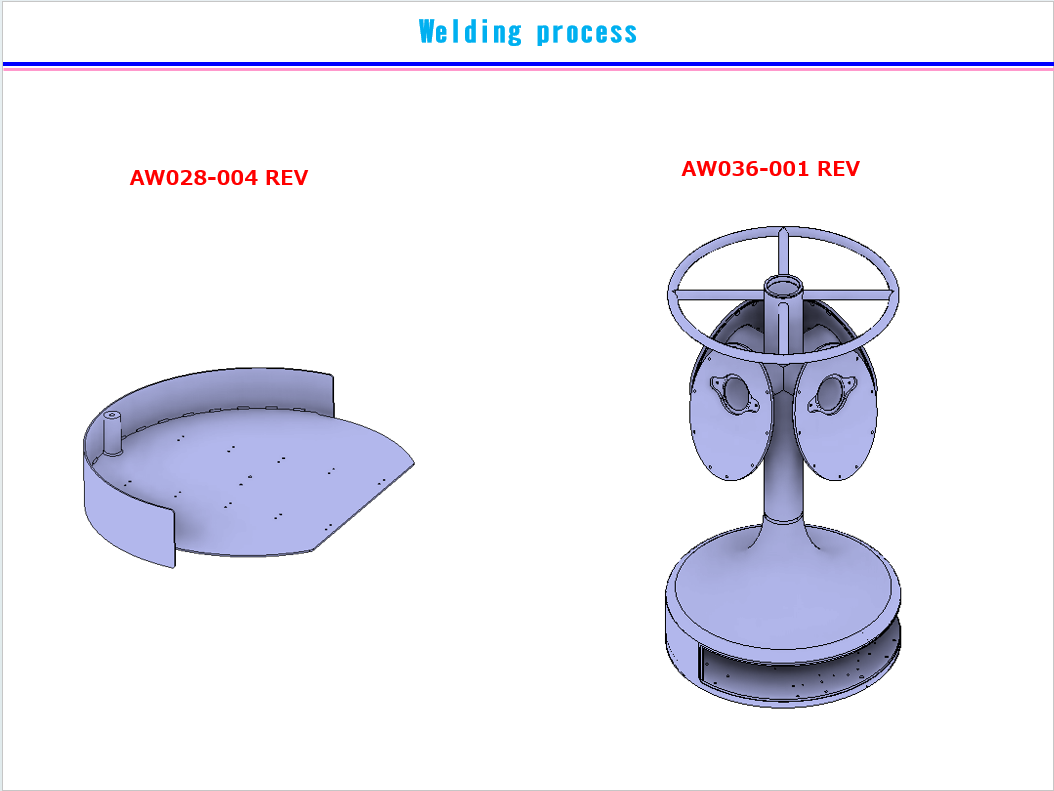

我们汇集技术部、工程部、生产部、品质部、PMC、采购部、包装部开会讨论评估后,给出如下加工工艺流程给到客户客户确认,交流优化、调整和修改后,形成相互都明白彼此的解决方案如下:

美国客户收到这个解决方案后,各个部门都高度认可并满意我们的做法及提出的可行的解决方案,并下PO采购订单给我们40套。

案例二

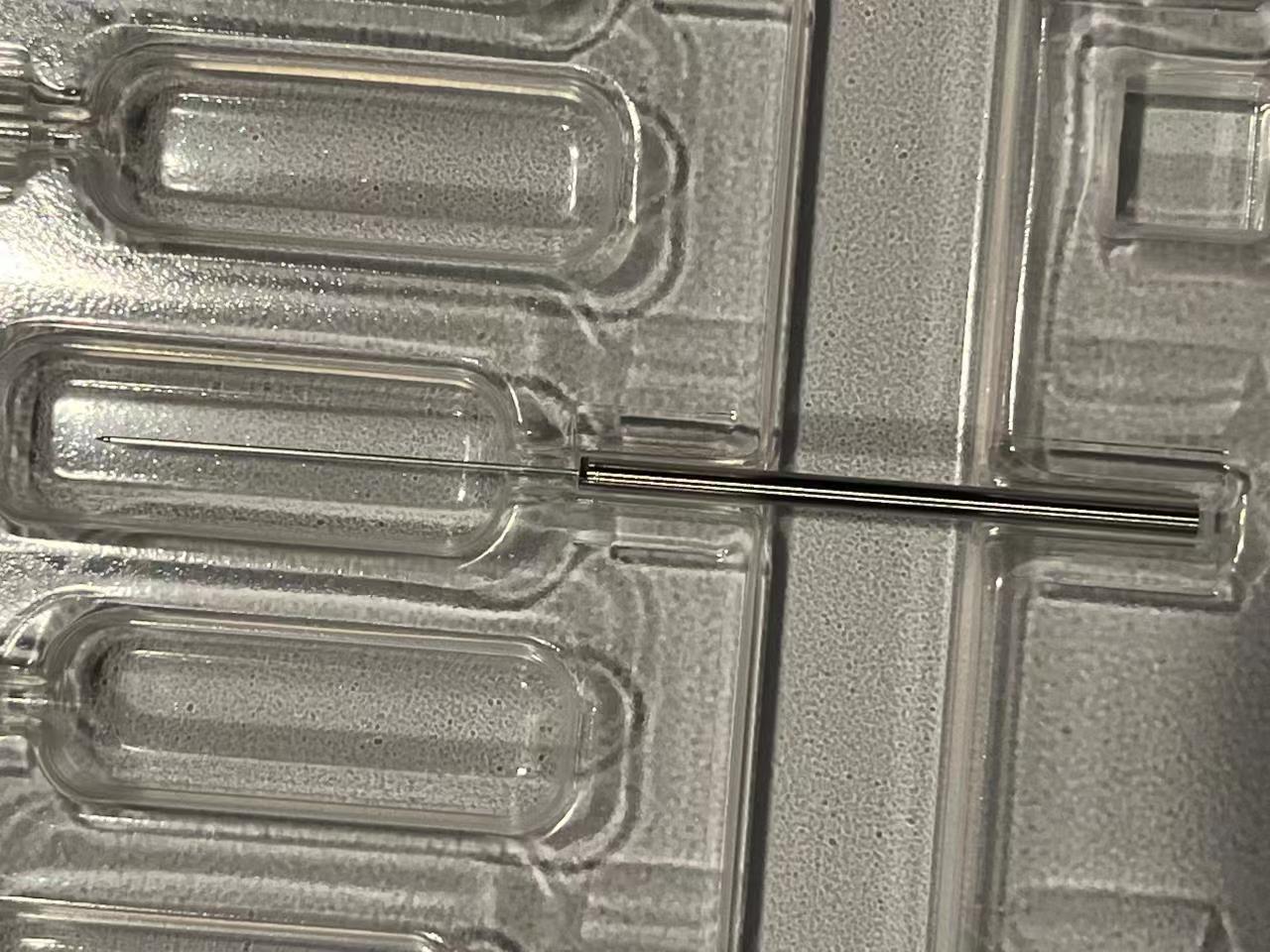

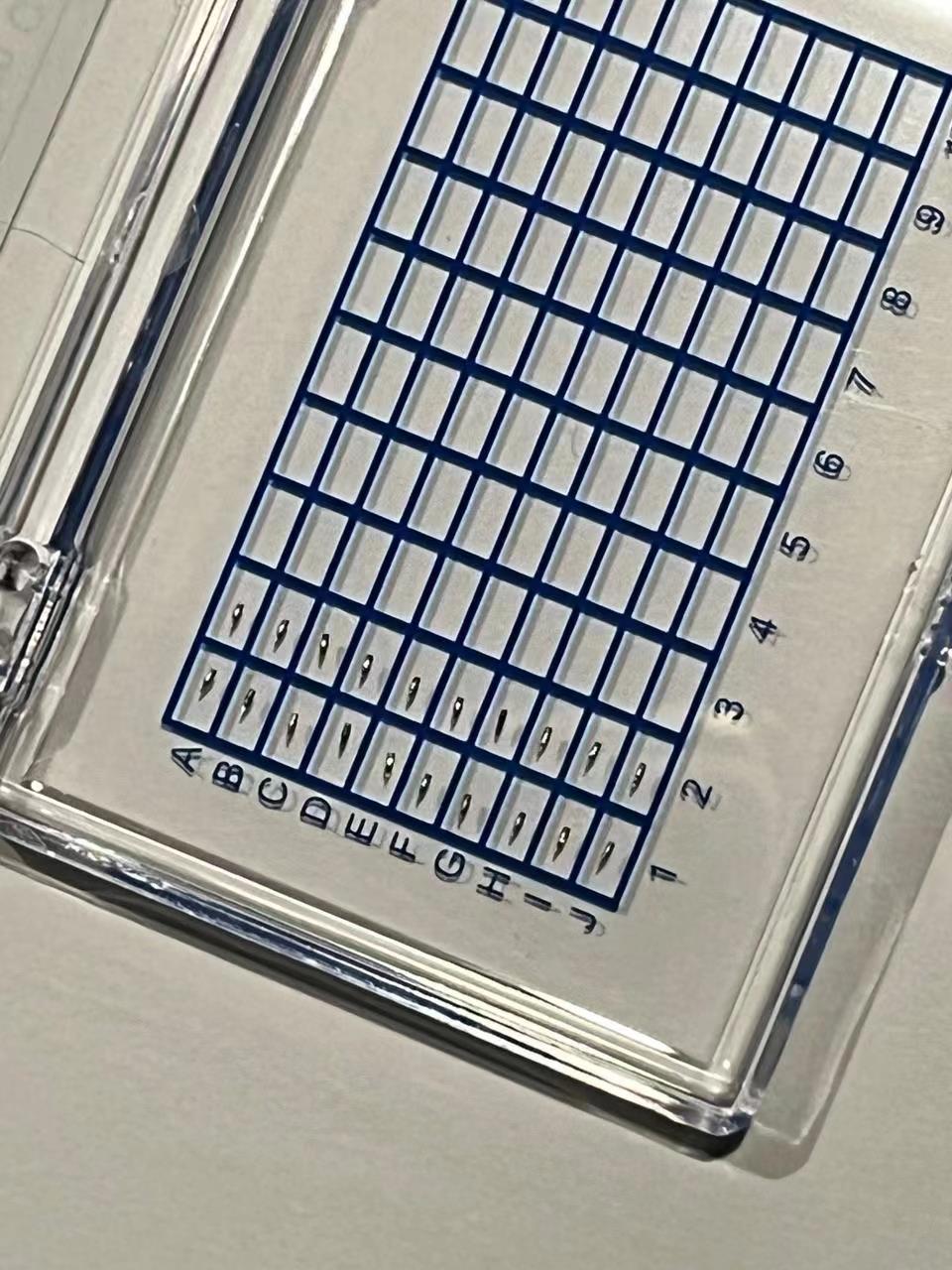

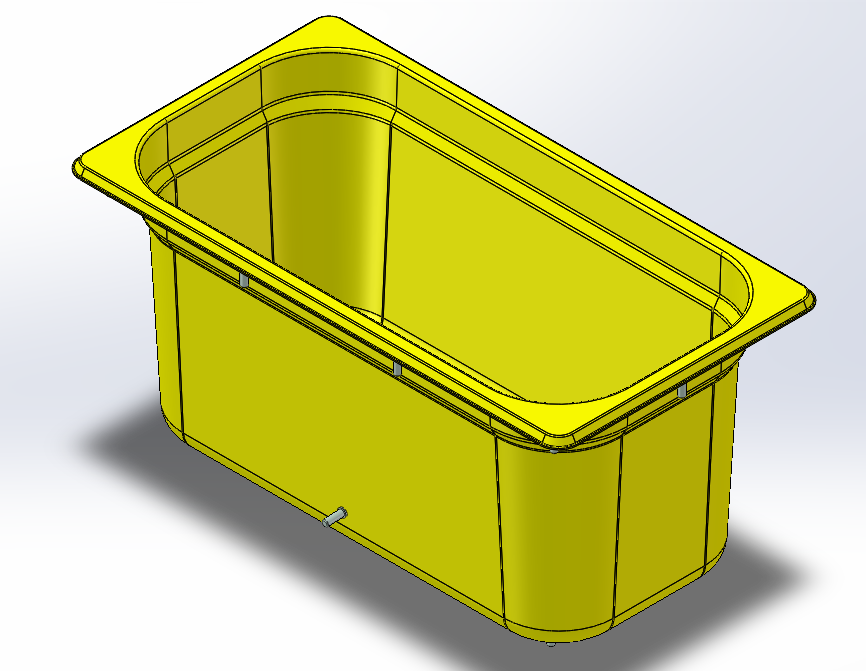

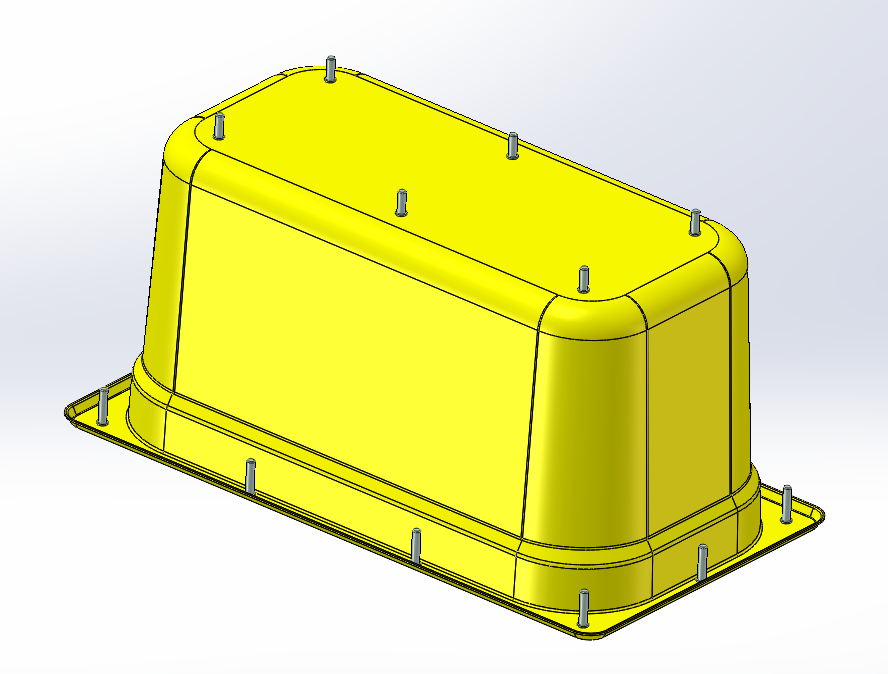

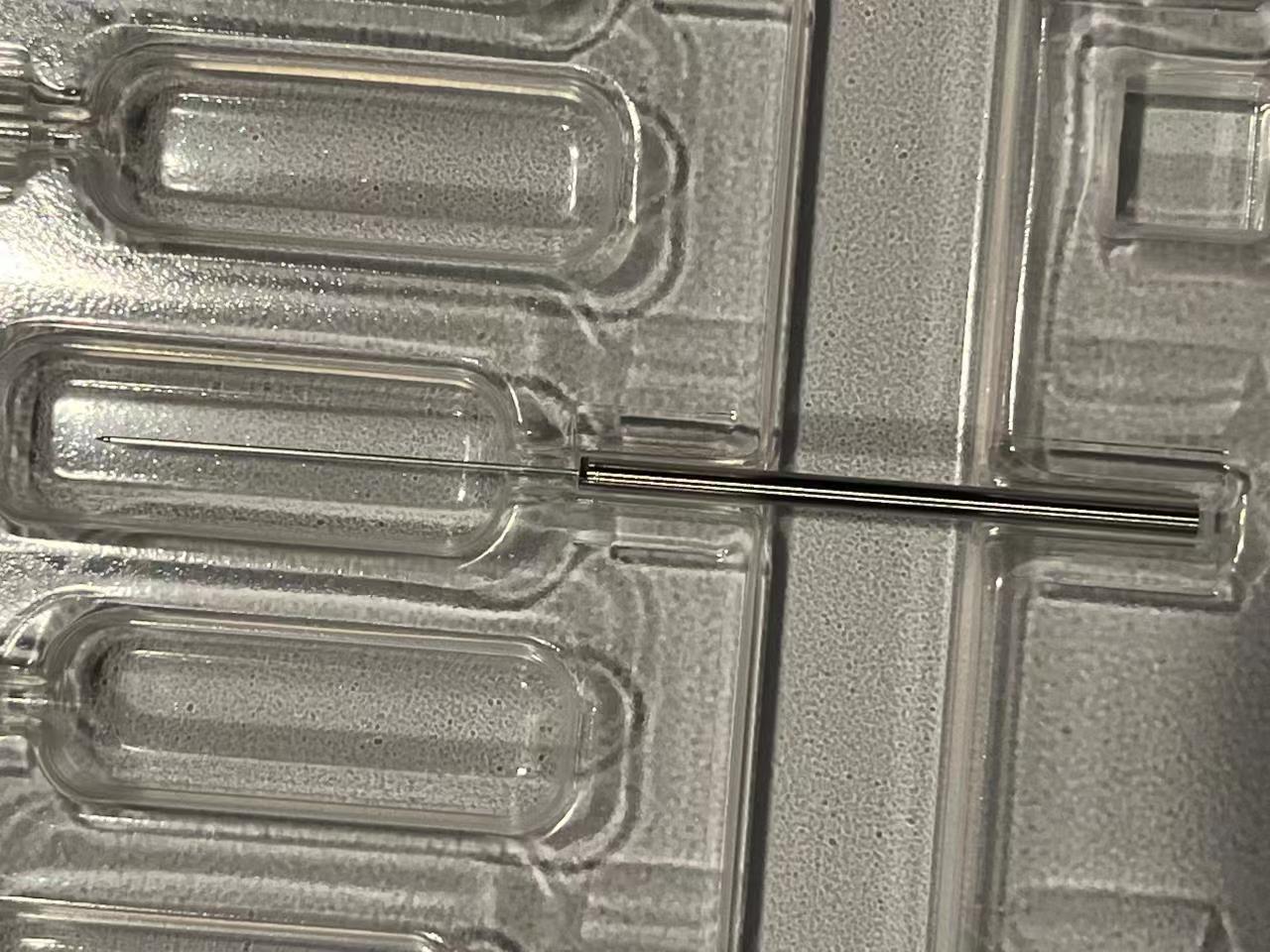

2025年9月,美国生物菌种培植恒温箱,316不锈钢,工序为模具拉伸、喷砂、电解、激光焊接螺丝钉,要求背面焊,正面无痕。他原来采用碰焊种钉,因为有正面很大的焊痕,我们用激光焊接精密焊接解决了无痕及凸包问题。风下图:

产品图纸

我们加工制造的实物图如下:

案例三:

2023年9月起,美国客户不锈钢医疗自动清洗消毒车。54套冲压拉伸模具、超薄316不锈钢材料、精密组焊、钝化,打包航空出货,项目为替换前20年内所有的塑胶产品,改为不锈钢,年更换量为5000台。

Stainless Steel Processing Business

1. Endorsement Cases from Key Industry Clients

Bühler (Switzerland) - Stainless Steel Food-Grade Machinery Industry

Kubota (Japan) - Stainless Steel Chemical & Pharmaceutical Machinery Industry

HP (United States) - Stainless Steel 3D Metal Printer Industry

Micro Matic (Denmark) - Stainless Steel Beer Equipment Industry

Cecotec (Spain) - Stainless Steel Consumer Product (High-Speed Blender) Industry

Grinnell (United States) - Stainless Steel Pipe Industry

Delta (Taiwan, China) - Stainless Steel Water-Cooled Tube Industry for AI Computing Power

Cooler Master - Stainless Steel Water-Cooled Tube Industry for AI Computing Power

Mainland China-based companies including Honggong, Shangshui, Haoneng, and Huawei - Stainless Steel Equipment & Parts Industry

2. Self-Introduction

With 18 consecutive years of stainless steel processing experience from 2007 to 2025, Jinzhu provides machining, sheet metal forming, and professional welding services to a total of 15 industries. These industries include food machinery, chemical machinery, medical and pharmaceutical equipment, new energy equipment (including equipment parts and functional components), photovoltaic equipment, semiconductor equipment, kitchen and bathroom, precision instruments and meters, 3C consumer electronics, building materials and decoration, outdoor equipment, luxury logo display stands and metal packaging, aerospace components, laboratory equipment components, as well as CNC machining, mold stretching, stamping and welding parts.

Jinzhu has also gained the trust and recognition of clients from countries and regions such as Europe, the United States, and Japan.

3. What products do we have?

· Laser Cutting Processing

· CNC Bending Processing

· CNC Stamping Processing

· CNC Rolling Processing

· TIG/MIG Welding Processing

· Laser Welding Processing

· Grinding and Polishing

· Spraying or Electropolishing

· Assembly

· Inspection

· Packaging and Shipping

4. Key Introduction to the Principles of Core Products

Welding (especially TIG/MIG welding processing and laser welding processing)

We can achieve extreme-quality results that meet customers’ requirements. This is supported by 20 years of welding solutions, which effectively address numerous pain points related to materials science, structure, appearance, functionality, application, and cost.

5. Why Choose Us?

1. We have over 20 years of extensive and comprehensive experience in solving problems related to overseas product applications and requirements, supported by numerous actual mass-production cases.

2. While possessing our own core competitiveness, we also have strong upstream and downstream resources to assist in problem-solving.

3. We have the capability of process iteration and the ability to develop new products with high certainty.

6. What Advantages Do We Have?

1. We have extensive industry application experience. When a customer informs us of their industry, we can quickly retrieve process solutions from our past customer database of application experiences, and communicate drawing requirements and product requirements. This effectively reduces development time and ensures that the customer’s design requirements are accurately met.

2. When our own conditions and capabilities are insufficient (mainly due to bottlenecks in hardware processing equipment and special processes), we have sufficient upstream and downstream resources to jointly solve the problems, and can professionally and effectively select and manage these Tier 2 (T2) suppliers.

3. We can identify unreasonable aspects of a customer’s design, or situations where subsequent manufacturing processes are difficult to implement (or can be implemented but at excessively high costs leading to waste). For these issues, we can put forward effective suggestions for ID improvements, optimizations, or even design changes, and submit them to the customer for review and confirmation. In fact, numerous customers have benefited from this capability of ours, enabling their projects to be successfully implemented on schedule.

7. FAQs

Q1: Material issue – Does it meet the requirements?

A: Regarding materials, we always provide materials with international standard compositions in accordance with the drawing requirements, and issue material certificates as proof.

Q2: How to ensure the consistency of products during the processing?

A: We can design and manufacture professional tooling for product processing, submit it to the customer for discussion and confirmation, and formulate the processing SOP (Standard Operating Procedure) based on the confirmed tooling to guide production.

Q3: How to ensure the yield rate of products during production?

A: We hold ISO9001 quality management system certification. In strict compliance with the quality system requirements, we implement full closed-loop control over all links in the product processing process, including operators, machinery and equipment, materials, process methods, processing environment (including turnover, placement, and safety), and inspection. We also follow the processes of incoming material inspection, in-process inspection, and outgoing inspection to ensure a 100% yield rate.

Q4: How to ensure on-time delivery with guaranteed quality and quantity?

A: We use production and delivery management software to dynamically display the delivery date required by the order, the arrival time and status of in-transit materials, as well as the completion time and status of each production process.

In case of abnormalities, the software will display corresponding color alerts, and allow uploading of photos of abnormal products and marking the problematic positions on drawings. At the same time, we will immediately arrange for an investigation into the cause: if the issue is related to the customer, we will communicate with them promptly; if it is an internal issue, we will immediately find solutions to resolve it and restore the process to normal (marked in green), ensuring the production process proceeds to the next step.

All processes are traceable, allowing us to identify the specific time node, work team, and even the individual operator involved. All time settings are based on the delivery time we committed to the customer through communication, and we only allow early delivery, not delays. This ensures on-time delivery.

8. Ordering Process

When engaging and communicating with a customer, we firstly ask the customer to fill out a Customer Requirement Information Form -> The chief engineer convenes personnel from the business, technology, engineering, production, quality, procurement, and PMC (Production and Material Control) departments to evaluate the customer’s products and requirements -> The content of this evaluation meeting will be organized into clear communication points, which the business follow-up specialists use to contact with the customer for discussion and confirmation -> Once we fully understand the customer’s requirements and the customer also fully understands our proposal, and a mutual agreement is reached on technical details, drawings, quantity, quality requirements, and delivery requirements -> we will issue a quotation -> After the customer confirms the quotation, either the customer or we will issue a commercial contract, and both parties will confirm the terms with each other -> Subsequently, the customer issues an official PO (Purchase Order) –> We then initiate the production and delivery process based on the previously confirmed technical document and the PO -> Dynamic confirmation documents are generated during the production process and after completion -> The customer issues an acceptance confirmation form -> Makes payment in accordance with the commercial contract -> Finally, the goods are shipped via logistics.

9. Customer Cooperation Feedback

All customers provide a feedback form after receiving the goods, which is stored in the project information feedback section. In case of complaints, we will issue an 8D quality improvement report, and the improvement plan confirmed by the customer will also be recorded in the project information. This ensures that when placing a repeat order, the next order can be executed in accordance with the corrected method after improvement.

10. Submit the requirement form

After communicating with our business staff, if customers decide to choose us and have the intention to cooperate with us, please submit basic information via the requirement form. We will respond and provide feedback within 24 working hours.

Stainless Steel Processing Cases:

1. Food-grade stainless steel products

Project Overview

· Country: Switzerland

· Industry: Food Machinery

· Material: 304 Stainless Steel

· Quantity: 200 pieces/year

· Pain Point: The customer requires that replacing the original non-environmentally friendly brazing process with a welding method, and establishing a single-piece flow lean production supply mode.

Project Challenges

1. Although the value is high, but the quantity is small.

2. Traditional TIG welding (known as argon arc welding in China) causes significant deformation, which leads to imprecise dimensions, and surface polishing is a bottleneck.

Solution

1. Laser welding (without medium) is adopted, which achieves minimal deformation and solves the environmental problem caused by lead in the original brazing process.

2. Sheet metal bending and assembly welding are used to address the challenge of single-piece flow.

3. Parts are pre-polished before welding to overcome the bottleneck of difficult polishing due to structural obstruction.

Project Success

1. The customer was pleasantly surprised to find a suitable process solution that meets almost all the requirements for addressing pain points.

2. The manufacturing process involves mold stretching, sheet metal bending, laser welding, polishing to a mirror finish, and finally electrolytic polishing to produce the finished product.

3. Using the solution provided by Jinzhu, the customer has expanded the application from the original 8 product models to 80 product models with similar structures across the entire group.

The Product Production and Fulfillment Process

1. Communication on Customer Product Drawing Requirements

2. Through laser cutting, mold stretching, CNC machining, bending, rolling (for rounding), TIG/MIG welding, laser welding, grinding and polishing, electrolysis, inspection, packaging, and shipment.

2. Medical-Grade Stainless Steel Products

American Stainless Steel Medical Device Customer (Ranked Top 3 in the Industry)

Project Overview

· Country: USA (a top 3 company in the medical device industry)

· Industry: Medical Devices (consumables, disposable—discarded after use and re-ordered for replenishment)

· Material: 316 Stainless Steel

· Quantity: Four types of products, with the quantity of each product exceeding 10,000 units.

· Value: The total order value of the four products is approximately 20 million RMB.

· Process Requirements: Mold forming + precision machining + precision laser welding (micro-deformation) + polishing + cleaning + inspection

· Pain Points:

Ø Medical devices have extremely high requirements; production is to be carried out in China, while certification is completed by the customer in the USA (certification has already been obtained);

Ø It is difficult to find manufacturers capable of precision laser welding;

Ø Professional cleaning conditions and sterile packaging are required;

Ø Professional optical inspection equipment is required.

Project Challenges

1. There are no issues with processing or welding (laser welding).

2. Cleaning and inspection are feasible.

Solution

Laser welding (without medium) is adopted, which results in minimal deformation. Basically, laser welding is universally used in medical devices.

Summary:

1. We provide customers with the following products and services, including the overall solutions for products.

production process:

A: Laser cutting processing

B: CNC bending processing

C: CNC stamping processing

D: CNC rolling (rounding) processing

E: TIG/MIG welding processing

F: Laser welding processing

J: Grinding and polishing, spraying or electrolytic polishing, assembly

There are a total of seven processes, namely A, B, C, D, E, F, and J. These seven processes:

1. Each individual process can be independently formed into an order;

2. An order can also be formed by combining any two or three of these processes;

3. Additionally, there are cases where customers need all seven services to form an order;

4. There is another scenario: when a customer has secured six of these processes but only cannot find a provider for laser welding, they will also come to us. They may even request their existing suppliers to designate us for the laser welding service—this is because neither the customer nor their suppliers have found a laser welding partner in the market that delivers better results than we do.

5. During communication and cooperation, since laser welding technology is crucial yet relatively niche, customers may sometimes ask us - Jinzhu, to act as the primary supplier to undertake the order. This allows us to coordinate with other secondary suppliers (who offer common services easily available in the market) to support our operations.

2. The specific products and services we provide to customers cover the following key words/terms

1. Products and Services:

A:Basic Metal Materials Category

1、 Metal Sheet

2、 Stainless Steel

3、 Aluminum Alloy

4、 Brass Plate

B:Metal Processing Form Category

1、 Metal Fabrication - Core Service Terms

2、 Sheet Metal Fabrication - Targeted Customer Group

3、 Laser Cutting Service - Technical Buyer

4、 Metal Bending Service - Supporting Processing

5、 CNC Machining Parts - Demand for Precision Parts

6、 Metal Stamping Parts - Automotive/Electronic Supply Chain

7、 Welding Service - Keywords for Processing Capabilities

8、 TIG/MIG Welding Service, Laser welding service

9、 Stainless steel welding (TIG/MIG): (TIG/Gas Tungsten Arc Welding, MIG/Gas Metal Arc Welding)

C:Finished Products and Components Category

1、 Custom Metal Parts – OEM buyer

2、 Precision Metal Components - High-end Manufacturing

3、 Metal Cabinet - Electrical/Control Equipment

4、 Metal Bracket - Pan-Industrial Applications

5、 Metal Enclosure - Protection of Electronic Equipment

6、 Architectural Metalwork - Engineering Projects

D:Industry Application Scenarios

1、 Industrial Metal Fabricator - B2B customer

2、 Food Grade Stainless Steel –Food and Catering Equipment Suppliers

3、 Medical Device Metal Parts - High-Demand Fields

4、 Stainless Steel Equipment and Components for the Semiconductor Industry

5、 Automotive Metal Parts - Auto Parts Supply Chain

6、 Food processing equipment parts: (Core Applications of Stainless Steel)

7、 Medical device components: (High Precision, Stainless Steel/Titanium Alloy)

8、 Pharmaceutical equipment parts: (Sanitary-Grade Stainless Steel)

9、 Semiconductor equipment parts: (High-Cleanliness Stainless Steel/Special Alloys)

10、 Marine components: (Salt Spray Resistant Stainless Steel/Aluminum Alloy)

11、 Automotive metal parts: (Various Types of Steel/Aluminum Alloy)

12、 Architectural metalwork: (Stainless Steel/Aluminum Alloy Decoration/Structure)

13、 HVAC components: (Stainless Steel/Copper Pipe Fittings)

14、 Machinery spare parts: (Various Types of Metal Parts)

15、 Electronics enclosure suppliers

16、 Telecommunication metal parts

17、 Medical equipment metal housing

18、 Automotive sheet metal components

19、 Solar panel mounting brackets

E:Core Product & Process Keywords

1、 Stainless steel fabrication:

2、 Stainless steel machining:

3、 Stainless steel components:

4、 Stainless steel parts:

5、 Stainless steel products:

6、 Stainless steel structures:

7、 Stainless steel assemblies:

8、 Sheet metal fabrication

9、 Metal stamping

10、 Laser cutting services

11、 CNC bending

12、 Metal enclosure fabrication

13、 Precision sheet metal

14、 Custom metal parts

15、 Chassis fabrication

16、 Metal brackets OEM

17、 Welding assembly

18、 welding fabrication services

19、 welding outsourcing

20、 robotic welding services

21、 stainless steel welding

22、 aluminum welding

23、 sheet metal welding

24、 structural steel welding

F:Keywords for Procurement Intent

1、 Supplier of metal components:

2、 Outsource metal fabrication:

3、 Custom metal parts manufacturer:

4、 Metal parts vendor:

5、 High precision metal parts:

6、 welding supplier

7、 welding vendor

8、 welding sourcing

9、 welding company

10、 welding service provider

J:Customer Type Keywords

1、 OEM sheet metal supplier

2、 Metal fabrication sourcing

3、 Contract manufacturing RFQ

4、 Industrial equipment manufacturers

5、 Hardware importers

6、 Machinery parts buyers

There are a total of seven major categories: ABCDEFJ. The products and services under these seven categories have the following characteristics:

1. Each category can independently form a single product or service on its own;

2. Any combination of two or three of these categories can also form a product or service order;

3. Sometimes, customers may require services from all seven categories to form an order;

4. There is another scenario: when a customer has sourced six of the categories but cannot find a provider for laser welding, they will also come to us. They will ask their existing suppliers to designate us to provide laser welding services, because neither the customer nor their suppliers have found a better supporting laser welding service provider in the market than us.

5. For customers in need of products or services from the above seven categories, we are the preferred supplier. Please contact us.

Case 1:

In October 2025, a well-known biopharmaceutical company in the United States requested us to handle the production and manufacturing of the following complete product.

The customer provided drawings and communicated their requirements.

After we assembled the Technical Department, Engineering Department, Production Department, Quality Department, PMC (Production Material Control), Purchasing Department, and Packaging Department for a meeting to discuss and evaluate, we provided the following processing flow to the customer for confirmation. After communication, optimization, adjustment, and revision, a solution that both parties fully understand was finally formed as follows:

After receiving this solution, the U.S. customer's various departments highly recognized and were satisfied with our approach and the feasible solution which we proposed, and subsequently placed a purchase order (PO) with us for 40 sets.

Case 2:

In September 2025, for the constant-temperature incubator used for biological strain cultivation in the United States (material: 316 stainless steel), the processes included mold stretching, sandblasting, electrolysis, and laser welding of screws. The requirement was to perform welding on the back with no traces left on the front.Previously, the customer used spot welding for screw planting, which resulted in large weld marks on the front. We solved the problems of residual traces and convex bumps by adopting precision laser welding.

See below: Product Drawings

The physical photos of the products we processed and manufactured are as follows:

Case 3:

Since September 2023, we have been collaborating with a U.S. customer on stainless steel medical automatic cleaning and disinfection carts. The project involves 54 sets of stamping and stretching molds, ultra-thin 316 stainless steel materials, precision assembly welding, passivation, and packaging for air shipment. This project aims to replace all plastic products used in the past 20 years with stainless steel alternatives, with an annual replacement volume of 5,000 units.